-

Negative Electrode Slurry Mixing: A critical first step impacting battery performance and lifespan. Graphite (active material), carbon black (conductive agent), and a binder (like PVDF) are precisely blended into a uniform, stable paste. This paste is later coated onto copper foil to form the negative electrode.

-

Positive Electrode Slurry Mixing: An equally vital step directly influencing electrochemical performance and longevity. Cathode active materials (e.g., LCO, NCM, LFP), conductive agents, binders, and additives are uniformly mixed to create a dense, coatable slurry.

-

Coating: A precision-critical step where the slurries are uniformly applied onto copper foil (anode) or aluminum foil (cathode). Coating uniformity and consistency are paramount, directly determining battery performance and lifespan.

-

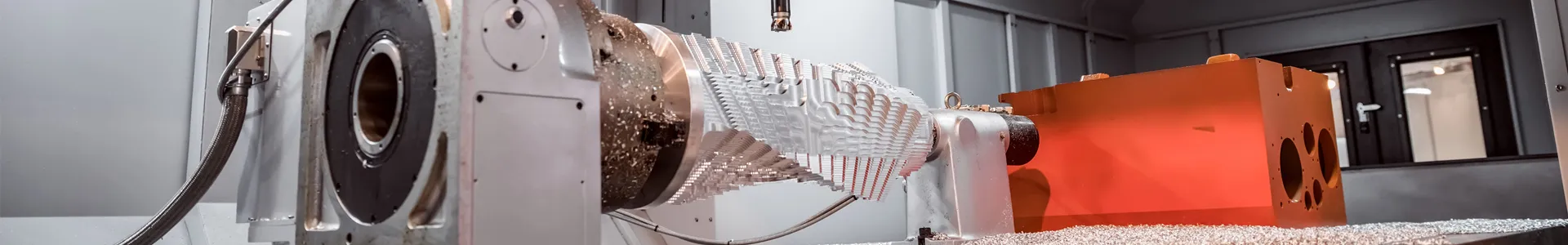

Calendering (Rolling/Pressing): A key process enhancing performance and consistency. Calendering machines compact the coated anode and cathode materials using rollers, increasing electrode density and uniformity. This improves electrochemical performance and ensures safety and reliability.

-

Slitting: A precision cutting process where large coated electrode sheets are slit into narrower strips according to exact width specifications for subsequent assembly. Precision cutting with clean edges is essential to prevent damage affecting performance.

-

Electrode Drying: An essential step for removing residual moisture and volatile organic compounds (VOCs) from the electrodes. Thorough drying is crucial for performance and safety, as residues can react with lithium ions during operation, degrading performance or creating hazards.

-

Winding: A core process assembling the battery cell. The anode, cathode, and separator are precisely wound into either a cylindrical shape or a flat pouch structure. This step directly defines the cell's capacity, performance, and safety characteristics.

-

Can Insertion (Housing): Marks the transition of the cell core into a complete battery component. The dried and wound cell core is carefully placed into its metal casing (can or pouch), providing physical protection and ensuring safety and performance stability.

-

Spot Welding: A key joining technique. It uses resistance heating to create localized high temperatures, melting metal to form strong welds connecting electrode tabs to terminals or busbars, ensuring reliable electrical connections.

-

Electrolyte Filling (Liquid Injection): A vital step involving the precisely controlled injection of liquid electrolyte into the cell. The electrolyte forms the ion-conducting pathway, enabling reversible lithium-ion movement between the electrodes. This critically impacts electrochemical performance, stability, and safety.

-

Cap Welding (Sealing): The final sealing step where the cap (or sealing layer for pouches) is hermetically attached to the cell housing (can). This provides physical protection against environmental factors (dust, moisture, corrosion) and safely isolates the internal positive and negative components to prevent short circuits.

-

Cleaning: Thoroughly removes dirt, impurities, and residues from the exterior of the assembled cell. High cleanliness is essential for performance and longevity, as contaminants could interfere with operation or cause failures.

-

Formation ("Activation"): The crucial "activation" step. The cell undergoes initial controlled charge/discharge cycles. This activates the electrochemical materials and, critically, forms a stable Solid Electrolyte Interface (SEI) film on the anode. The SEI layer is vital for performance and safety: it prevents harmful side reactions between the electrolyte solvent and lithium ions, reduces irreversible lithium loss, and enables high efficiency, long cycle life, and safe operation.