1. Influence of Electrode Material Properties

The slitting quality of electrode sheets is significantly affected by their physicochemical properties. Generally:

-

Ductile materials exhibit delayed crack initiation during shearing, resulting in a larger sheared depth and a greater proportion of smooth, bright zones on the slit edge.

-

Brittle materials fracture more readily under identical conditions, leading to a larger fracture zone with more tearing marks and a reduced bright zone.

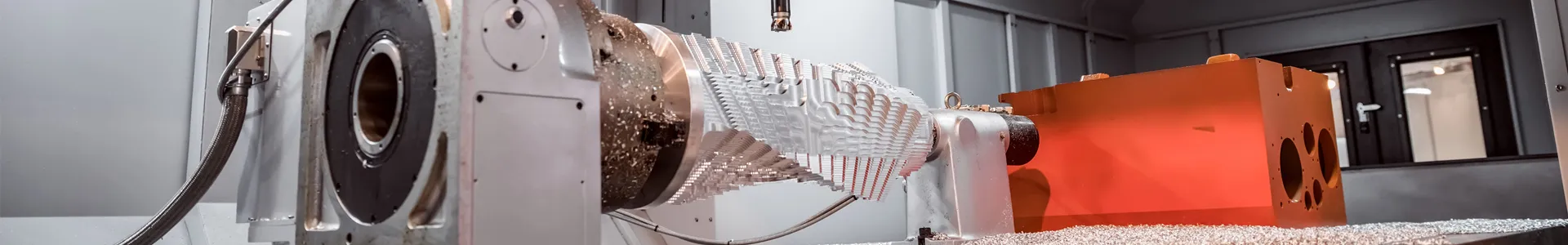

2. Case Study: LFP Electrode Metal Debris Issue

Problem:

During LFP (LiFePO₄) electrode slitting, significant metal debris was observed on slit edges and coated areas (Fig. 1).

Initial Hypotheses:

-

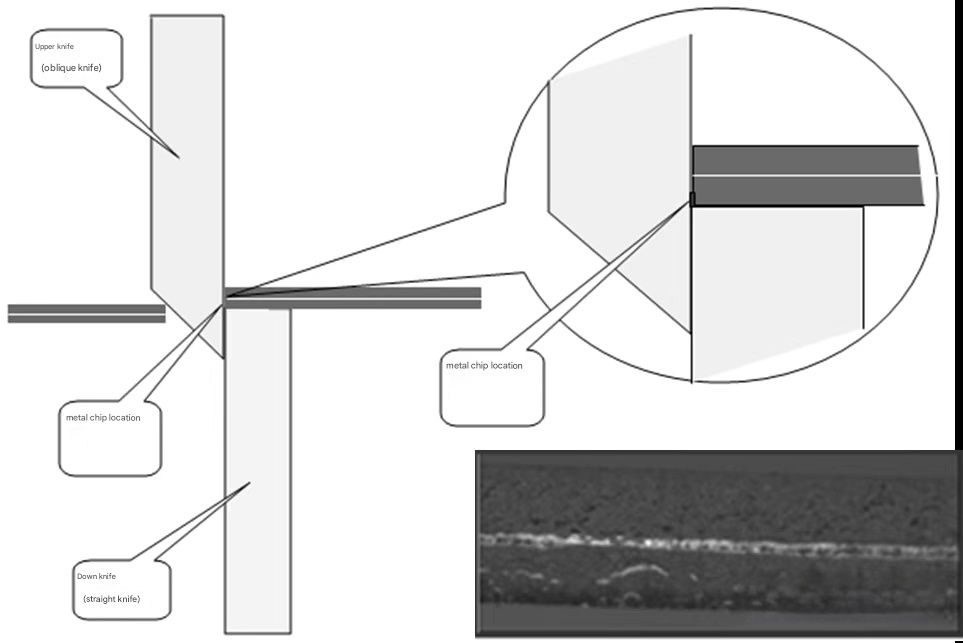

Chip Accumulation: Angle between upper/lower blades traps debris, later transferring to the film.

-

Material Ductility: High toughness of LFP electrodes causes transverse tension during shearing, pulling aluminum debris from the foil.

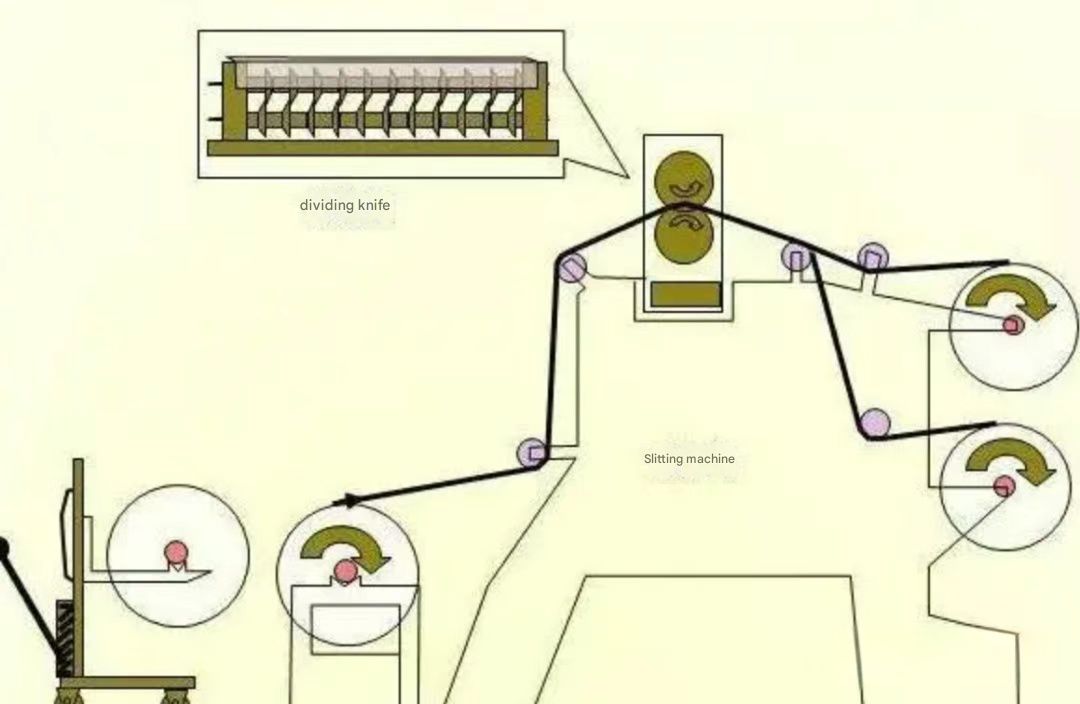

-

Poor Chip Removal: Tight blade contact prevents timely debris clearance, leading to residual debris transfer (Fig. 2).

Hypothesis Validation:

-

Hypothesis 1: Debris appeared at 5 mm on new blades (vs predicted 8.5 mm) → Invalid.

-

Hypothesis 2: Material properties require validation via comparative testing.

-

Hypothesis 3: Blade design requires optimization.

Experiment 1 - Material Comparison (Identical Blade Setup):

| Material | Slit Edge Observation |

|---|---|

| LFP | Continuous long metal debris |

| LCO | No debris, but rough surface |

| NCM | Powder-like metal debris |

Conclusion: Material formulation critically impacts slitting quality. Tailored slitting parameters are essential for different electrode systems and thicknesses.

3. Slitting Burr Classification & Risks

-

Type I Burrs (Hard Burrs): Protrude from the current collector but remain attached.

-

Type II Burrs (Aluminum Powder): Detach and deposit on electrode surfaces.

Critical Risk: Residual aluminum powder on cathodes can pierce separators after hot pressing, causing cell short circuits (failure rate: 7%–10%).

4. Improvement Strategies for Aluminum Powder Shedding

4.1 Improvement 1: Alignment Adjustment

-

Blade Holder Leveling: Used precision leveler on base

-

Infeed/Outfeed Roller Alignment: Adjusted rollers to ensure:

-

Sheet entry/exit height flush with lower blade apex.

-

Smooth sheet travel without over-height.

Result: Edge quality improved, but aluminum shedding persisted.

-

4.2 Improvement 2: Blade Runout Inspection

-

Measured radial runout of upper/lower blade shafts.

Result: Runout <10 μm (within spec) → Not root cause.

4.3 Improvement 3: Blade Angle Optimization

| Scheme | Blade Configuration | Outcome |

|---|---|---|

| Scheme 1 | Upper: 16° bevel, Lower: 90° | Reduced lateral force → No significant improvement |

| Scheme 2 | Upper/Lower: 16° bevel | Further force reduction → Slight improvement |

| Scheme 3 | Upper: Pointed, Lower: Grooved (Draw-cut) | Severe shedding due to non-specialized holder → Worsened |

4.4 Improvement 4: Felt + Alcohol Cooling

-

Installed alcohol-moistened felt pads contacting upper blades to:

-

Remove adhered aluminum particles.

-

Cool blades to prevent edge blunting.

Result:

-

-

No aluminum powder on slit edges.

-

Blade lifespan increased from 10,000 m to 200,000 m

5. Conclusion

Material formulation directly determines electrode ductility during slitting, affecting debris generation and edge morphology. For challenging materials like LFP/NCM:

-

Precision alignment of blades/rollers is necessary but insufficient alone.

-

Optimizing blade angles reduces lateral forces but may not eliminate shedding.

-

Integrating felt cleaning with alcohol cooling proves most effective, eliminating debris and extending tool life 20-fold. Future work should focus on specialized draw-cut systems for ductile electrodes.