I. Roller Press Fundamentals

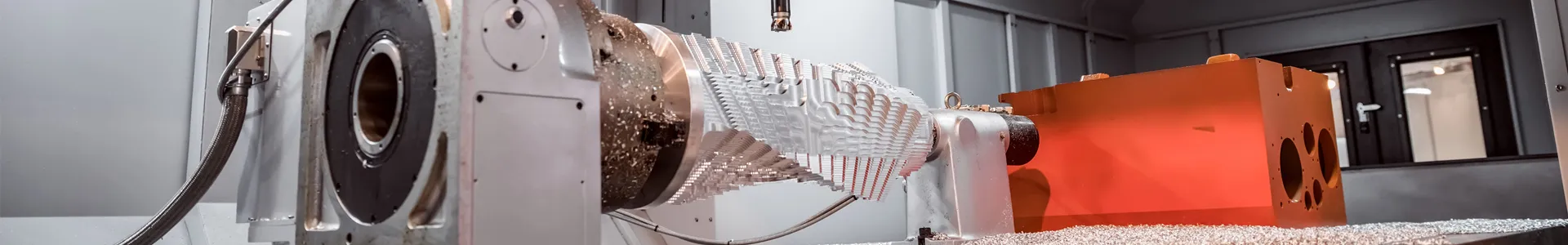

To improve the density of the surface material and thickness uniformity of battery electrodes, both the cathode and anode sheets must undergo rolling after the coating process. This step is known as electrode roller pressing. Currently, lithium-ion battery manufacturers globally primarily use two-high roller presses. A typical two-high press consists of two cast steel compaction rollers, a motor, and a drive shaft. Mainstream models have roll diameters of 500 mm and barrel lengths ranging from 500 mm to 700 mm. However, the thickness consistency of the pressed electrode across its width direction is often poor. To meet precision requirements for thickness uniformity, the ratio of roll length to diameter is often kept small, ultimately limiting the width of the electrode that can be pressed.

The complete roller pressing process involves securing the coated electrode sheet onto the unwinding mechanism, correctly threading it through the gap between the two rollers, and connecting it to the winding system. Once the rolling mode is activated, the motor drives both the top and bottom rollers to rotate simultaneously. The winding mechanism pulls the electrode sheet steadily through the roll gap, compacting it to the required density. When not in use, the rollers should be coated with a thin layer of oil to prevent rust. Before operation, this oil layer must be wiped clean with anhydrous ethanol, and the unwinding/winding mechanisms along with the automatic edge guiding system must be cleaned. Therefore, an excellent roller press must incorporate the following eight functional modules:

-

Roller Pressure Adjustment & Rapid Response: Adjusting the pressure between the rollers is essential for increasing the compaction density of the electrode's active material. Due to factors like intermittent coating and alternating single/double sides, the pressure adjustment must respond quickly.

-

Roll Gap Adjustment & Precise Reset: Adjusting the gap between the rollers is necessary to achieve the desired electrode thickness. Changes in coating methods or the need for electrode splicing require rapid gap adjustments followed by precise resetting.

-

Tension Adjustment (Pre/Post Rolling) & Rapid Response: Adjusting tension before and after rolling helps control the flatness of the electrode sheet. Sudden changes in rolling line speed are common, and rapid tension response is crucial for preventing web breaks.

-

Stepless Roller Speed Control & Line Speed Synchronization: During start-up, shutdown, or according to process needs, the rollers must be capable of stepless speed variation while maintaining synchronized line speeds.

-

Electrode Rolling Temperature Adjustment: Adjusting the rolling temperature directly affects the deformation resistance and plastic deformation amount of the electrode during compaction.

-

Roller Deflection Correction: During rolling or temperature changes, rollers inevitably experience axial bending deflection and radial crown deformation. Correcting this deflection directly impacts electrode thickness uniformity and compaction density consistency.

-

Intelligent Control for Rolling Process: As rolling speeds and automation levels increase, functions like automatic loading/unloading, automatic splicing, automatic pressure application, automatic gap adjustment, and online monitoring demand closed-loop or even intelligent control.

-

Roller Cleaning & Maintenance: Adhesion of powder to the roller surfaces during pressing is common. Maintaining clean rollers reduces wear and improves electrode surface quality. Ease of maintenance is also essential.

Laboratories typically use manual screw-pressure type electrode rolling mills. Pressure is applied to the rollers by setting the roll gap value, without additional pressure devices. Consequently, the actual pressure is generally low, limiting the achievable compaction density of the pressed electrode. Furthermore, the maximum roll gap is constrained by the mechanical design, typically preventing the rolling of very thick electrodes.

Additionally, electrode rolling is categorized into cold rolling and hot rolling. Hot rolling is widely adopted internationally, while cold rolling remains predominant domestically. Compared to cold rolling, hot rolling offers advantages:

(1) Removes moisture from the electrode; reduces internal stress within the electrode, minimizing stress-release-induced defects during slitting or die-cutting.

(2) Reduces material rebound after rolling; lowers the deformation resistance of the electrode, facilitating better electrolyte absorption by the active material.

(3) As the electrode material reaches a molten state during heating: Hot rolling increases the adhesion between the active material and the current collector, reducing active material shedding during charge/discharge cycles and improving battery cycle life.

Regarding rolling schedules: Methods include single-pass rolling and multi-pass rolling. Multi-pass rolling is more complex but can reduce electrode rebound, improve surface gloss, and enhance thickness uniformity.

II. Purpose of Roller Pressing

The compaction density of the electrode significantly impacts the battery's electrochemical performance. Within a certain range, as compaction density increases, the distance between active material particles decreases, contact area increases, and pathways/bridges for ionic conduction multiply. Macroscopically, this manifests as reduced internal battery resistance. However, if compaction density is too high, particles become overly compacted, increasing electronic conductivity but potentially reducing or blocking lithium-ion pathways. This hinders capacity utilization, increases polarization during discharge, lowers voltage, and reduces capacity. Conversely, if compaction density is too low, particle spacing is large, facilitating lithium-ion movement and strong electrolyte absorption. However, insufficient particle contact impedes electronic conduction, also leading to increased polarization during discharge.

Necessity of Rolling: After coating and drying, the peel strength between the active material and the current collector foil is very low. Rolling is essential at this stage to enhance adhesion strength and prevent delamination during electrolyte immersion and battery use.

Objectives of Rolling include:

-

Ensuring a smooth and flat electrode surface, preventing burrs on the coating surface from piercing the separator and causing short circuits.

-

Compacting the coated material to reduce electrode volume, thereby increasing battery energy density.

-

Promoting closer contact between active material and conductive agent particles, improving electronic conductivity.

-

Enhancing the bonding strength between the coating material and the current collector, reducing active material shedding during cycling, and improving battery cycle life and safety performance.

III. Electrode Rolling Process and Control

1. Rolling Process

The electrode rolling process involves the electrode sheet being pulled into the rotating rollers by friction, where it undergoes compressive deformation. Unlike steel rolling, where iron molecules elongate longitudinally and spread transversely without density change, electrode rolling is primarily a compaction process for the electrode materials. The rolling force applied should neither be too large nor too small; it must align with the characteristics of the electrode materials.

-

Region I (Sliding Stage): As rolling force initially increases gradually, electrode density rises rapidly. This is due to particle displacement and pore structure filling within the electrode material. This stage exhibits the fastest density increase rate.

-

Region II (Transition Stage): As the pore structure is largely filled from Stage I, the coating material density reaches a plateau. Increased compression deformation resistance is encountered. Although rolling force continues to increase, the density increase rate slows significantly. Microscopically, particle displacement is minimal, and significant displacement movement hasn't yet begun.

-

Region III (Compaction Stage): Once rolling force exceeds a certain threshold, density starts increasing again with force, but the rate gradually decreases. This occurs because particles begin significant displacement again. When force reaches a critical point, severe material deformation causes work hardening, making further deformation difficult. Consequently, density increases minimally with further force application.

2. Rolling Control

Basic Mechanism: Electrode rolling is a form of powder rolling, aiming to increase the compaction density and uniformity of the active material, enhance active material adhesion, and improve surface roughness. The process adheres to the principle of mass conservation.

-

Vertical Compaction vs. Longitudinal Extension: The force exerted by the rollers is the resultant of vertical and horizontal pressures, determined by the active material compression amount and the roll bite angle. For a given compression, vertical pressure dominates with a small bite angle, while horizontal pressure dominates with a large bite angle. Compaction density depends on vertical pressure; longitudinal elongation depends on horizontal pressure.

-

Compaction Density Uniformity & Surface Roughness: Assuming uniform coating thickness, compaction uniformity depends on the parallelism of the rollers' contact generatrix. Influencing factors include roll concentricity, barrel cylindricity, bearing precision, equipment rigidity/stability, and roll gap adjustment at both ends. Surface roughness depends on active material particle size and roll surface roughness.

-

Current Collector Extension & Active Material Particle Sliding: Aluminum or copper foils exhibit minimal extension under large-diameter rollers. However, bonded active material particles slide under horizontal pressure, pulling the current collector and causing extension, which affects electrode flatness and conductivity.

-

Local Extension/Compression & Internal Stress Imbalance: Coating thickness variations and generatrix parallelism errors lead to non-uniform local compaction density. Coexistence of local extension and surrounding compression creates uneven internal stress, impacting electrode flatness.

-

Compaction Density, Elongation & Roll Diameter: The bite angle directly influences compaction density and elongation, and is itself determined by roll diameter. Larger diameter means smaller bite angle; smaller diameter means larger bite angle.

-

Thickness Rebound, Rolling Speed & Ambient Humidity: Slower speeds reduce elastic deformation (rebound). Paradoxically, beyond a certain speed, rebound also decreases, attributed to ambient humidity. Moisture absorption affects active material surface alkalinity and rebound.

-

Internal Stress Imbalance & Tension Control: Rolling involves both compression and extension. Inlet tension affects internal stress distribution; outlet tension affects flatness.

-

Hot Rolling & Deformation Resistance: Generally, material deformation resistance decreases with increasing temperature, while plastic deformation increases. Hot rolling may also reduce roll surface wear. However, clear advantages of hot over cold rolling for electrodes remain elusive, highlighting the complexity of influencing factors.

IV. Problems During Rolling and Solutions

-

Uneven Electrode Thickness: Causes include uneven coating thickness, roll concentricity error, roll cylindricity error, non-parallel contact generatrix, roll axial bending, poor equipment rigidity/stability.

-

Transverse Thickness Variation: Left-right thickness inconsistency. If unrolled electrode thickness is uniform, adjust left/right rolling pressure. Monitor thickness regularly during rolling.

-

Longitudinal Thickness Variation (Rebound): Thickness meets spec post-rolling but increases after slitting. Caused by high internal moisture or excessive rolling speed. Solutions: Hot rolling, speed control.

-

-

Edge Wave ("Sickle Bend"): Primarily caused by non-parallel roll generatrices or uneven coating thickness at edges. Thicker edges experience higher rolling force, leading to uneven transverse density and severe curling, detrimental to slitting. Control relies on coating quality management (slurry surface tension, pump pressure, line speed, rolling pressure).

-

Wavy Edges: Mainly caused by excessive elongation. Contributing factors: Small roll diameter, low pre-rolling tension, high compression ratio, convex coating edges at sides. Uneven extension between coated (extending) and uncoated (non-extending) foil areas creates transverse wrinkles.

-

Dark Streaks on Surface: Caused by roll surface vibration marks, large roll cylindricity error, or low/uniform pre-tension.

-

Edge Curling ("Curl"): Result of excessive elongation. Solutions: Increase roll diameter, reduce compression ratio, adjust pre/post tension.

-

Web Breaks: Caused by unstable/uniform tension, lack of rapid tension response, severe edge coating buildup. Local coating defects (e.g., large particles, uneven mass loading) can cause localized stress leading to foil rupture or breakage. Solutions: Control winding tension, prevent large particle contamination.

-

Uneven Edge Tension: Caused by non-parallelism between roll axes and guide roller axes. Solution: Adjust roller axis parallelism.

-

Roll Surface Pitting: Roll surface fatigue pitting. Caused by inhomogeneous roll material/heat treatment microstructure (poor fatigue resistance) and related to surface roughness.

-

Electrode Thickness Rebound: Caused by significant residual elastic deformation or high ambient humidity. Solutions: Hot rolling, slow rolling, high-speed rolling, reduce relative humidity.

-

Poor Electrode Flatness: Caused by uneven rolling deformation, low/uniform pre/post tension, or coating thickness errors.

-

Operator Errors: E.g., scraping material during thickness measurement, failure to mark defects. Solutions: Enhanced training and awareness.

V. Impact of Rolling Process on Battery Cells

1. Impact on Electrode Processing State

The ideal post-rolling state is a smooth, uniformly glossy surface, absence of significant waves in uncoated areas, and minimal curling. However, operator skill and equipment condition can cause issues, directly impacting slitting (uneven width, burrs) and winding (severe curling creates gaps between electrode/separator, leading to separator overlap and stress concentration points after hot pressing, degrading cell performance).

2. Impact on Lithium-Ion Battery Performance

-

Specific Energy/Power: Faraday's law dictates electrode capacity is proportional to active material mass. Rolling directly affects active material compaction density, thus impacting specific energy.

-

Energy Density/Power Density: Similarly, active material compaction density directly influences energy and power density.

-

Cycle Life: Rolling directly affects active material adhesion to the current collector, impacting its detachment/shedding during cycling, thereby influencing cycle life.

-

Internal Resistance: Active material compaction density and shedding significantly impact Ohmic and electrochemical resistance, affecting various battery performance metrics.

-

Safety: Uniformity of active material compaction density and surface roughness induced by rolling directly affect lithium plating on the anode, copper dissolution on the cathode, and dendrite growth at sharp points, potentially leading to safety incidents.

VI. Conclusion

Numerous factors influence lithium-ion battery manufacturing. Effectively resolving potential process issues at each stage directly reduces material waste, improves the quality and efficiency of subsequent processes (assembly, electrolyte filling, packaging), enhances the quality and consistency of the final product, lowers production costs, and ultimately strengthens the market competitiveness of lithium-ion battery products.