Electrode coating generally refers to the process of evenly applying a uniformly mixed slurry onto a current collector and subsequently drying the organic solvent within the slurry. The quality of coating significantly impacts battery capacity, internal resistance, cycle life, and safety, ensuring uniform electrode coating. The choice of coating method and control parameters critically affect lithium-ion battery performance, primarily manifested in the following aspects:

-

Coating Drying Temperature Control: If the drying temperature is too low during coating, the electrode may not dry completely. If the temperature is too high, the rapid evaporation of organic solvents inside the electrode can cause surface cracking or peeling of the coating.

-

Coating Areal Density: If the areal density is too low, the battery capacity may fail to reach the nominal value. If it's too high, it leads to material waste. More seriously, excessive positive electrode capacity can cause lithium plating, forming lithium dendrites that pierce the separator, leading to short circuits and safety hazards.

-

Coating Dimensions: Coating dimensions that are too small or too large may prevent the negative electrode from fully covering the positive electrode within the cell. During charging, lithium ions deintercalated from the positive electrode move into the electrolyte in areas not covered by the negative electrode, reducing the positive electrode's effective capacity. In severe cases, lithium dendrites can form inside the battery, potentially piercing the separator and causing an internal short circuit.

-

Coating Thickness: Coating thickness that is too thin or too thick affects the subsequent calendering process, compromising the consistency of electrode performance.

Furthermore, electrode coating is crucial for battery safety. Before coating, the 5S methodology (Sort, Set in order, Shine, Standardize, Sustain) must be implemented to ensure no particles, debris, or dust contaminates the electrode during the process. Contaminants can cause internal micro-shorts, potentially leading to fire or explosion in severe cases.

Coating Equipment and Process Selection

The broad coating process includes: unwinding → splicing → threading → tension control → coating → drying → edge alignment → tension control → edge alignment → rewinding. Coating is complex, with numerous factors influencing its outcome, such as: manufacturing precision of coating equipment, stability of equipment operation, dynamic tension control during coating, airflow volume during drying, and temperature control curves. Therefore, selecting the appropriate coating process is extremely important.

Generally, choosing a coating method requires consideration of the following aspects: number of coating layers, wet coating thickness, rheological properties of the coating liquid, required coating precision, coating substrate or base material, and coating speed.

Beyond these factors, the specific characteristics of lithium-ion battery electrode coating must be considered:

-

Double-sided single-layer coating.

-

Thick wet slurry coating (100–300 μm).

-

Slurry is a non-Newtonian, high-viscosity fluid.

-

High precision requirements for electrode coating, similar to film coating.

-

Substrates are aluminum foil and copper foil with thicknesses of 10–20 μm.

-

Electrode coating speeds are generally lower compared to film coating speeds.

Considering these factors, laboratory equipment often uses the doctor blade method; consumer lithium-ion batteries frequently employ roll-to-roll transfer coating; while power batteries predominantly use the slot-die extrusion method.

-

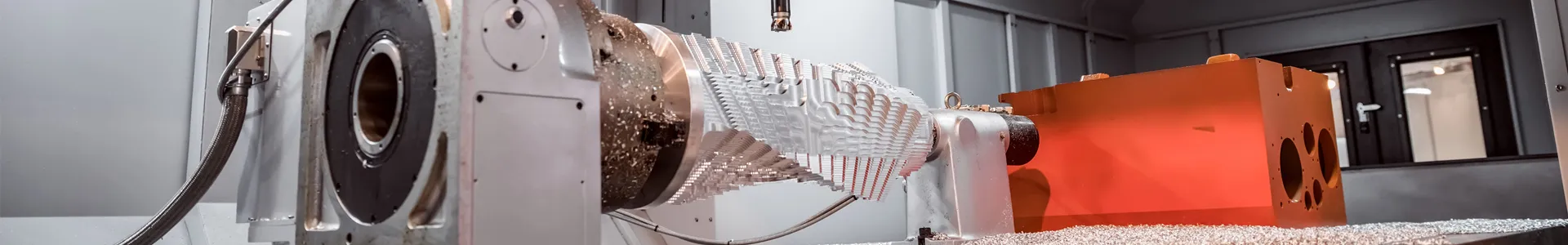

Doctor Blade Coating: The foil substrate passes over a coating roller and directly contacts the slurry reservoir. Excess slurry is applied to the foil. As the substrate passes between the coating roller and the doctor blade, the gap between the blade and the substrate determines the coating thickness, scraping off excess slurry which flows back, forming a uniform coating layer on the substrate surface. A key type is the comma blade. The comma blade, a critical component, typically features a comma-shaped edge machined along the generator of a cylindrical roller surface. This blade offers high strength and hardness, facilitates control over coating amount and precision, and is suitable for high solid-content and high-viscosity slurries.

-

Roll-to-Roll Transfer Coating: The coating roller rotation carries the slurry. The slurry transfer amount is regulated by the gap at the comma blade. The slurry is then transferred to the substrate via the rotation of the backing roller and the coating roller. This process involves two basic steps:

-

The coating roller rotation carries slurry through the metering roller gap, forming a slurry layer of specific thickness.

-

This slurry layer is transferred onto the foil substrate via the opposing rotation of the coating roller and backing roller to form the coating.

-

-

Slot-Die Coating: As a precision wet coating technology, the working principle involves the coating liquid being extruded and dispensed through a slot in the coating die under controlled pressure and flow rate, transferring onto the substrate. Compared to other methods, it offers advantages such as high speed, high precision, uniform wet thickness; a closed system preventing contamination; high slurry utilization; stable slurry properties; capability for multi-layer coating; and adaptability to a wide range of slurry viscosities and solid contents, providing greater flexibility compared to transfer coating.

Coating Defects and Influencing Factors

Reducing defects, improving coating quality and yield, and lowering costs are critical aspects of coating process research. Common issues include thick leading/thin trailing edges, thick edges on both sides, spot-like dark stains, surface roughness, and foil exposure (bare spots). Leading/trailing thickness can be adjusted via coating valve or intermittent valve timing. Thick edge problems can be mitigated by adjusting slurry properties, coating gaps, or slurry flow rates. Surface roughness, unevenness, and streaks can be improved by stabilizing the foil, reducing speed, or adjusting air knife angles.

-

Substrate - Slurry:

-

The basic physical properties of the slurry, particularly viscosity, influence coating. Electrode raw materials, slurry formulation ratios, and binder types affect slurry viscosity. Excessively high viscosity hinders continuous, stable coating and affects quality.

-

The slurry's uniformity, stability, edge, and surface effects are influenced by its rheological properties, directly determining coating quality. Techniques like theoretical analysis, coating experiments, and fluid dynamics finite element analysis can be used to study the "coating window" – the range of process parameters enabling stable coating and uniform layers.

-

-

Substrate - Copper and Aluminum Foil:

-

Surface Tension: The surface tension of Cu/Al foil must be higher than that of the coating solution. Otherwise, the solution will not spread evenly on the substrate, leading to poor coating quality. A general rule is that the solution's surface tension should be at least 5 dynes/cm lower than the substrate's. Surface tension can be adjusted via formulation or substrate surface treatment. Measuring both should be a quality control test.

-

Thickness Uniformity: In processes like doctor blade coating, uneven substrate thickness across the web (cross-machine direction, CMD) leads to uneven coating thickness, as the gap between the blade and substrate controls the thickness. Areas with thinner substrate will have thicker coating (more slurry passes through), and vice versa. Thickness variations in the substrate will directly cause corresponding variations in the final coated film. CMD thickness variations also cause winding defects. Precise control of raw material thickness is essential to avoid this.

-

Static Electricity: During unwinding and passage over rollers, significant static electricity can build up on the substrate surface. This attracts dust from the air and rollers, causing coating defects. Electrostatic discharge can create "static mark" defects on the coating surface and, more severely, cause fires. Static problems are worse in low-humidity conditions (e.g., winter). Effective countermeasures include maintaining higher ambient humidity, grounding the coating line, and installing anti-static devices.

-

Cleanliness: Impurities on the substrate surface cause physical defects like bumps or dirt particles. Controlling raw material cleanliness during substrate production is crucial. Online web cleaning rollers are an effective method to remove substrate contaminants, improving material quality and reducing losses, though they cannot remove all impurities.

-

Coating Uniformity

Coating uniformity refers to the consistency of coating thickness or adhesive amount distribution within the coated area. Better consistency implies better uniformity. There is no single metric; it can be measured by the deviation (or percentage deviation) of thickness/adhesive amount at various points relative to the area average, or by the difference between maximum and minimum values within an area. Coating thickness is typically expressed in µm (micrometers).

Uniformity evaluates the overall coating over an area. In production, uniformity in the cross-machine direction (CMD, width direction) and machine direction (MD, length direction, substrate travel direction) are of primary concern. The causes, magnitudes of errors, and control methods for CMD and MD uniformity differ significantly. Generally, wider substrates (coatings) make CMD uniformity harder to control. Based on extensive online coating experience:

-

Substrate widths below 800mm: CMD uniformity is usually easy to ensure.

-

Substrate widths between 1300–1800mm: CMD uniformity can often be controlled well but requires considerable expertise and presents challenges.

-

Substrate widths above 2000mm: Controlling CMD uniformity is extremely difficult, mastered by very few manufacturers.

As production batch size (coating length) increases, MD uniformity can become a greater challenge than CMD uniformity. -